20 years of injection molding machine manufacturing experience

Provide dedicated injection molding machines for various industries

Xiamen Deqi Automation Co., Ltd.whose factory is located in Xiamen, China, has a full range of processing equipment, mainly CNC machining centers. It is a high-tech enterprise integrating R&D, manufacturing, sales and after-sales service for injection molding, bottle blowing, pipes and other special plastic machinery.

The company has brought together a large number of experts and management backbones in the plastic machine industry, and has in-depth research and understanding of customer needs, market changes, and the development of plastic machine technology and industry. The professional team has achieved the advantages of “precision, stability, energy saving and high efficiency” of Deqi molding machines. Compared with traditional technology injection molding machines, our energy-saving injection molding machines can save 25%-60% of electricity. Deqi Company pays more attention to the individual needs of customers and has developed special models for PET bottles, PVC/PPR pipe fittings, road walls, silicone bakelite, multi-material and other products, and provides customers with integrated solutions.

Numbers Speak

Provide special injection molding machines for various industries to customers around the world

Unique Designs

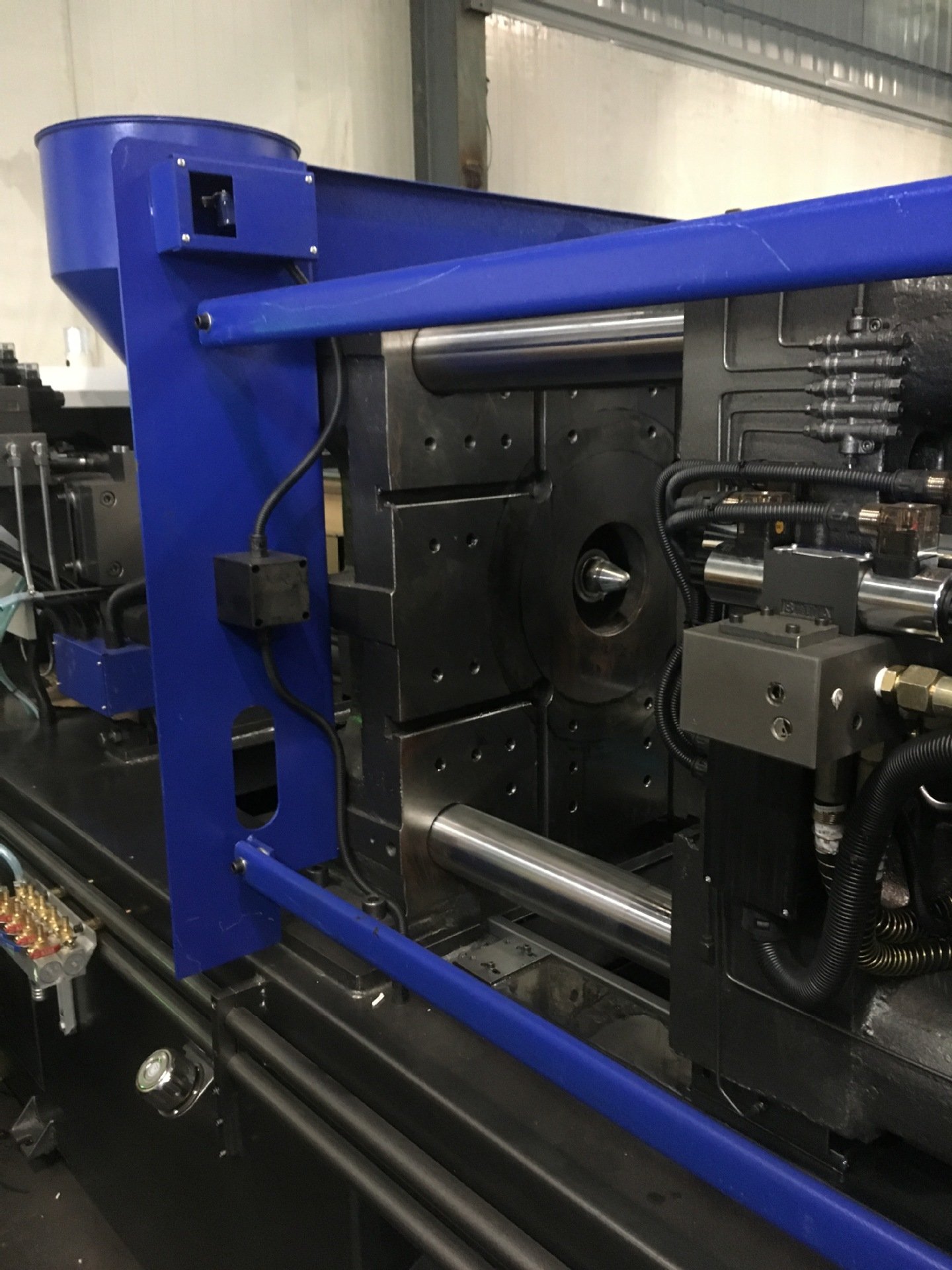

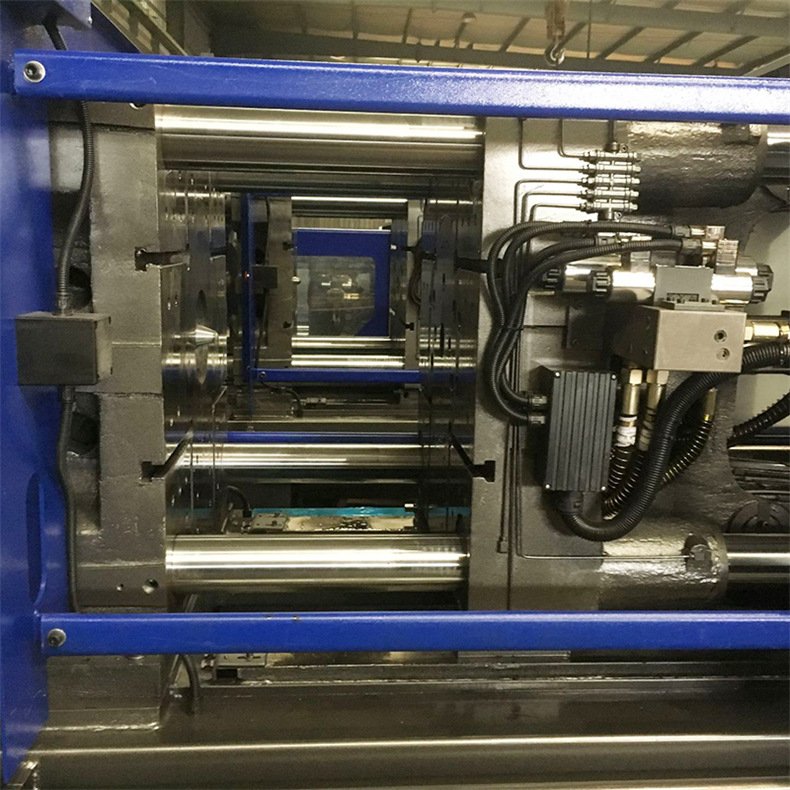

The injection component adopts double cylinder balanced injection and double guide column support. Rich special screw library for customers to choose to meet a variety of plastic materials forming and processing. It can also be matched with a variety of special injection molding devices to convenient customers. High-performance-low-speed hydraulic motor is used to directly drive screw premoliding.

High-End Quality

•Large torque hydraulic motor have stable preplastic quality, high precision electronic ruler position detection, accurate measurement.

•Multi-stage hydraulic injection speed and pressure, and multi-stage pressure holding can be set. The pressure holding switching point can be controlled from injection time, position and pressure to ensure the molding quality.

•Computer is used inMulti-stage preplastic back pressure and preplastic speed controlling, screw preplastic antisalivation, and automatic cleaning.

•Cold strat prevention function can ensure that screw and barrel are not damaged.

•PID temperature control is used to accurately hold the cylinder temperature.

•Using double guide column to support, and double balance to rapid injection.

Most popular

This is what makes us different

Hear from our customers.

Fast delivery

The fastest delivery time is 10 days.

24 hours after-sales service

7*24 hours after-sales service.

Best Offers

20% off on reordering.

Quality assurance

3 years long warranty.